OUR PRODUCTS RANGE

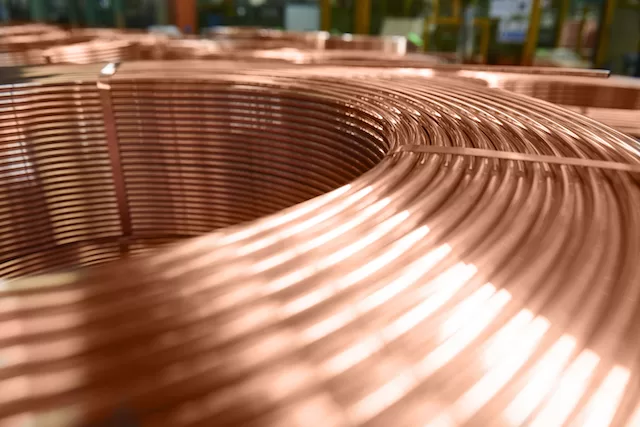

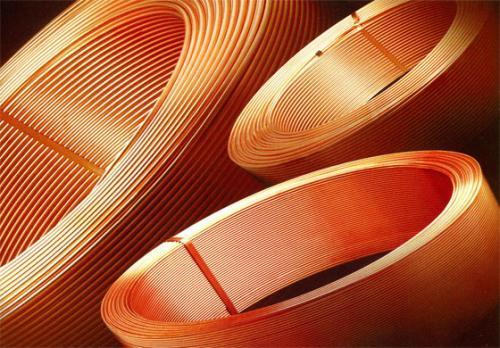

Abco Engineering Inc. is the leading Manufacturer of Copper LWC for ACR (Inner Crooved ) in Mumbai, India. The inner grooved copper tube boasts an even and compact structure, precise dimensions, and a normative and integral groove shape. Its low interior surface residuum contributes to an increased inside surface area of 65 to 100% compared to plain copper tubes of the same specifications. The heat transfer coefficient of the inner grooved copper tube is approximately 1.8 to 2.0 times that of its plain counterpart. This innovative design aligns with the evolving trend of high efficiency and energy-saving requirements in applications such as Air Conditioners, Assembly Type Air Conditioning Units, Residential Central Air Conditioning, and ShowCase Refrigerators.

The purpose of the inner grooved copper tube is to enhance the heat transfer characteristics of copper tubes and heat exchangers by incorporating spirally running grooves on the inner surface. The heat transfer coefficient of these tubes surpasses that of plain tubes by approximately 2 to 3 times. The increased internal surface area, along with the turbulent flow of refrigerant and uniform distribution around the tube, leads to enhanced efficiency. When integrated into fin block heat exchangers, the use of inner grooved tubes can boost the heat exchanger’s efficiency by up to 30%, depending on the application.

Benefits of utilizing inner grooved tubes include a smaller unit size with unchanged efficiency, cost savings in material, space efficiency, reduced fan size and noise levels, smaller compressors, and overall energy savings. The inner grooved copper tube represents an innovative solution for applications where improved heat transfer performance and energy efficiency are paramount.

packed individually by reel, 6-7 coils packed by one pallet

Copper IGT, LWC inner grooved copper tube, ASTM B819 Seamless Copper LWC Tubing for ACR Application, Copper LWC For ACR Supplier, Inner Grooved Copper Tubes, LWC Inner Grooved Copper Tubes, C12200 LWC Inner Grooved Copper Tube, Copper LWC for ACR(Inner Grooved) Supplier in Mumbai, India.

Applied to the Air Conditioner, the Assembly Type Air Conditioning Unit, the Residential Central Air Conditioning, Show Case Refrigerator, and so on.

Category: Copper Tube Tags: ACR, AS/NZS 1571, ASTM B280, Copper tube, JIS H3300

Temper: O60

| Product Code | Description |

| HTCD4 | Inner Grooved Coil 4mmxLWC, soft annealed |

| HTCD476 | Inner Grooved Coil 3/16″xLWC, soft annealed |

| HTCD5 | Inner Grooved Coil 5mmxLWC, soft annealed |

| HTCD6 | Inner Grooved Coil 6mmxLWC, soft annealed |

| HTCD635 | Inner Grooved Coil 1/4″xLWC, soft annealed |

| HTCD7 | Inner Grooved Coil 7mmxLWC, soft annealed |

| HTCD794 | Inner Grooved Coil 5/16″xLWC, soft annealed |

| HTCD952 | Inner Grooved Coil 3/8″xLWC, soft annealed |

| Specification | Outside Diameter (mm) | Bottom Wall Thickness (mm) | Groove Depth Hf (mm) | Number of Groove | Inclination Angle (Degree) | Fin Angle (Degree) |

| 7.00*0.25+0.18 | 7 | 0.25 | 0.18 | 50 | 18 | 40 |

| 7.00*0.27+0.15 | 7 | 0.27 | 0.15 | 50 | 18 | 40 |

| 9.52*0.27+0.16 | 9.52 | 0.27 | 0.16 | 70 | 18 | 40 |

| 9.52*0.28+0.12 | 9.52 | 0.28 | 0.12 | 65 | 15 | 53 |

| 9.52*0.28+0.15 | 9.52 | 0.28 | 0.15 | 60 | 18 | 40 |

| 9.52*0.28+0.20 | 9.52 | 0.28 | 0.20 | 60 | 18 | 40 |

| 9.52*0.28+0.20 | 9.52 | 0.28 | 0.20 | 60 | 18 | 53 |

| 9.52*0.30+0.20 | 9.52 | 0.30 | 0.20 | 60 | 18 | 53 |

| 9.52*0.34+0.15 | 9.52 | 0.34 | 0.15 | 60 | 18 | 53 |

| 9.52*0.34+0.20 | 9.52 | 0.34 | 0.20 | 60 | 18 | 53 |

| 9.52*0.45+0.20 | 9.52 | 0.45 | 0.20 | 60 | 18 | 48 |

| 12.7*0.35+0.25 | 12.7 | 0.35 | 0.25 | 65 | 18 | 53 |

| 12.7*0.35+0.25 | 12.7 | 0.35 | 0.25 | 65 | 18 | 65 |

| 12.7*0.41+0.20 | 12.7 | 0.41 | 0.20 | 70 | 18 | 65 |

| 12.7*0.41+0.25 | 12.7 | 0.41 | 0.25 | 60 | 18 | 65 |

| 12.7*0.45+0.20 | 12.7 | 0.45 | 0.20 | 50 | 18 | 53 |

| 15.87*0.4+0.28 | 15.87 | 0.40 | 0.28 | 75 | 18 | 53 |

| 15.87*0.4+0.28 | 15.87 | 0.40 | 0.28 | 60 | 18 | 53 |

| 15.87*0.58+0.3 | 15.87 | 0.58 | 0.30 | 75 | 18 | 48 |

| O.D. | Bottom Wall Thickness Tw | Fin Groove Depth Hf | |||

| Inch | mm | Inch | mm | Inch | mm |

| 0.1575 | 4 | 0.008~ 0.012 | 0.20 ~ 0.30 | 0.004~ 0.006 | 0.10 ~ 0.15 |

| 0.1875 | 4.76 | 0.008~ 0.014 | 0.20 ~ 0.35 | 0.004~ 0.006 | 0.10 ~ 0.15 |

| 0.197 | 5 | 0.008~ 0.014 | 0.20 ~ 0.35 | 0.004~ 0.006 | 0.10 ~ 0.15 |

| 0.2363 | 6 | 0.008~ 0.014 | 0.20 ~ 0.35 | 0.004~ 0.008 | 0.10 ~ 0.20 |

| 0.25 | 6.35 | 0.008~ 0.014 | 0.20 ~ 0.35 | 0.004~ 0.008 | 0.10 ~ 0.20 |

| 0.275 | 7 | 0.01~ 0.016 | 0.20 ~ 0.41 | 0.004~ 0.010 | 0.10 ~ 0.25 |

| 0.3125 | 7.94 | 0.01~ 0.016 | 0.20 ~ 0.41 | 0.004~ 0.010 | 0.10 ~ 0.25 |

| 0.375 | 9.52 | 0.01~ 0.016 | 0.20 ~ 0.46 | 0.004~ 0.012 | 0.10 ~ 0.30 |

Abco Engineering Inc. stands out as a premier manufacturer specializing in the production of copper pipes, tubes, and brass components. Renowned for excellence, our products find versatile applications across various industries including electrical systems, medical gas pipelines, HVAC and refrigeration, heat exchangers, and automotive sectors.

Shop No.1, Shreepati Castle,

“A” Wing, 11th Lane, Khetwadi, Grant Road,

Mumbai -400004, Maharashtra, India.

Contact No:-9930080011

E-mail ID: info@abcoenginc.in

Abco Engineering Inc. © 2023 Created with YUGASMI