OUR PRODUCTS RANGE

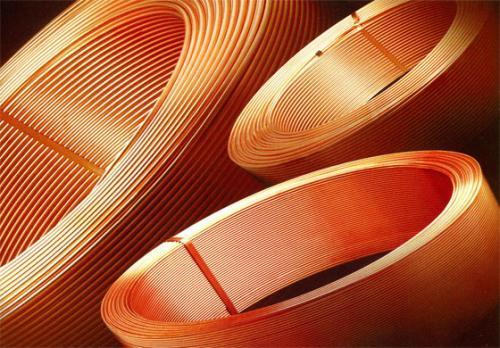

A level wound coil (LWC), a continuous length of securely coiled copper tube, finds diverse applications in HVAC and plumbing. Abco Engineering Inc offers a range of sizes, coil weights, and temperatures, ensuring fast and on-time delivery along with exceptional customer care.

Our Level Wound Copper Coil for Condenser (LWC) Tubes, with a minimum copper content of 99.9% as per IS-191, is available in Forged, Hot Rolled, Extruded, and Cold-worked finishes, meeting various dimensions and specifications. These tubes come in hard, half-hard, and soft conditions, making them suitable for a wide range of applications.

Due to the de-oxidized copper composition, these tubes are unaffected by reducing atmospheres, making them well-suited for welding and brazing applications. The applications for Level Wound Copper Coils include:

Choose Abco Engineering Inc for reliable and versatile Level Wound Copper Coils designed to meet your specific needs.

STANDARD:

ASTM B280, JIS H3300, AS/NZS 1571

PACKAGE:

Each piece is end-capped, Bundled with a plastic bag; then put in the wooden box or container.

Suitable for long production runs for industrial applications and available in ultrathin walls, LWC coil is mainly used for Air Conditioning, Refrigeration, and Heat Exchange.

Category: Copper Tube Tags: AS 1571 standard, ASTM B280, ASTM B68, ASTM B75 standard, Copper Coil, Copper tube, EN 12735 standard, JIS H3300, Level Wound Coil, LWC

LWC (Level Wound Copper Coil) For Condenser, Condenser Level Wound Coil Supplier, Level Wound Copper Coil Condenser, LWC Copper For Condenser, Mumbai, India

For the creation of new articles, this important detail must be specified. The direction of uncoiling can be:

a) Clockwise (standard). When the coil is in a horizontal position, the tube ending in the inner layer of the coil is at the bottom.

b) Anti-clockwise (optional). When the coil is in a horizontal position, the tube ending in the inner layer of the coil is at the top.

Temper: O60 or O50

Package: with unit weight 100kgs more and packed individually by reel, 6-7 coils packed by one pallet

| Product Code | Description |

| HTCC4 | LWC Plain 4mmxLWC, soft annealed |

| HTCC5 | LWC Plain 5mmxLWC, soft annealed |

| HTCC635 | LWC Plain 1/4″xLWC, soft annealed |

| HTCC8 | LWC Plain 8mmxLWC, soft annealed |

| HTCC952 | LWC Plain 3/8″mmxLWC, soft annealed |

| HTCC127 | LWC Plain 1/2″mmxLWC, soft annealed |

| HTCC14 | LWC Plain 14mmxLWC, soft annealed |

| HTCC1588 | LWC Plain 5/8″mmxLWC, soft annealed |

| HTCC1905 | LWC Plain 3/4″mmxLWC, soft annealed |

| HTCC2223 | LWC Plain 7/8″mmxLWC, soft annealed |

| copper alloy No. | chemical composition | temper | mechanical property copper | ||

| copper, % min, | Phosphorus (%) | tensile strength elongation | Elongation % | ||

| C12200 | 99.9 | 0.015-0.040 | O60 | ≥ 205 | ≥ 40 |

| C12200 | 99.9 | 0.015-0.040 | O50 | ≥ 245 | |

Abco Engineering Inc. stands out as a premier manufacturer specializing in the production of copper pipes, tubes, and brass components. Renowned for excellence, our products find versatile applications across various industries including electrical systems, medical gas pipelines, HVAC and refrigeration, heat exchangers, and automotive sectors.

Shop No.1, Shreepati Castle,

“A” Wing, 11th Lane, Khetwadi, Grant Road,

Mumbai -400004, Maharashtra, India.

Contact No:-9930080011

E-mail ID: info@abcoenginc.in

Abco Engineering Inc. © 2023 Created with YUGASMI