OUR PRODUCTS RANGE

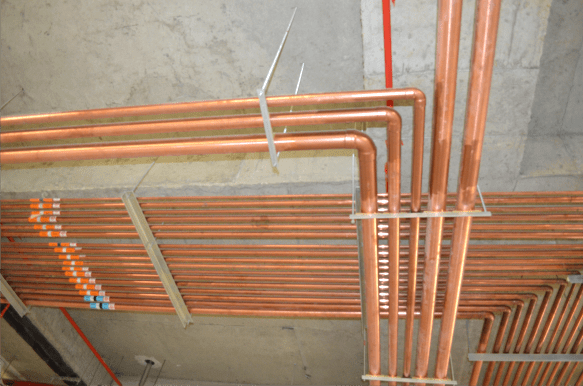

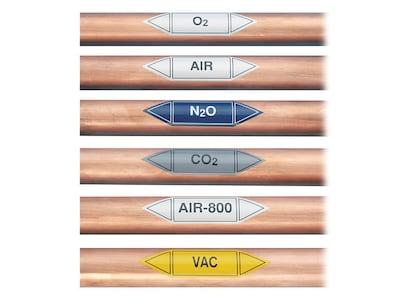

ABCO ENGINEERING INC takes pride in manufacturing Medical Grade Copper Pipes that are essential for Medical Gas Distribution systems. In hospitals, an uninterrupted supply of medical gas is crucial for various departments such as ICU, Operation Theater, Wards, Nursery, and more. Medical grade copper pipes provide the most effective solution for this purpose. Our pipes are manufactured in compliance with the highest quality standards, meeting 348/BS EN 1057 specifications. We ensure thorough inspections and quality control measures during the manufacturing process.

ABCO ENGINEERING INC offers medical grade copper tubes in various sizes ranging from 10mm to 108mm OD, with a wall thickness of 0.6mm to 2.0mm in Half Hard/Hard conditions, and a length of 3 meters as per international standards. We subject our medical grade copper pipes to Third Party Inspection agencies such as Lloyds, SGS, and TUV as per mandatory specifications demanded by our customers.

EN 13348 Copper Pipe MGPS, ASME SB280 Seamless Copper Pipes For Hospitals, EN 13348 Medical Gas Copper Pipe, BS EN 1057 Copper Pipes, ASTM B-280 Medical Pipes, ASTM B-819 Seamless Copper Pipe, Copper Clean Medical Pipe Stockist, Medical Grade Copper Pipes, ASTM B819 Seamless Copper Pipe MGPS, BS 2871/EN 1057 Medical Copper Pipes, EN 13348 Medical Grade Copper Pipes Supplier in Mumbai, India.

| SPECIFICATION | CHEMISTRY | COPPER GRADE | TEMPER | ||||||||||||||

| TEST METHOD | Optical Emission Spectra | ||||||||||||||||

| EN 1057 | Cu + Ag : min. 99.90% P:0.015 % to 0.040 % | Cu-DHP or CW024A | R200 | annleaded | |||||||||||||

| R250 | half hard | ||||||||||||||||

| R290 | hard | ||||||||||||||||

| ASTM B 88 | Cu + Ag : min. 99.90% P:0.015 % to 0.040 % | C12200, Cu-DHP | Annealed,Coils & Straight | O60 | |||||||||||||

| Annealed, Straight Lenghts | O50 | ||||||||||||||||

| Drawn,Straight Lengths | H58 | ||||||||||||||||

| ASTMB 306 | Cu + Ag : min. 99.90% P:0.015 % to 0.040 % | C12200, Cu-DHP | Drawn,Straight Lengths | H58 | |||||||||||||

| SPECIFICATION | BENDING TEST | DRIFT EXPANSIONS TEST | NON DESTRUCTIVE TEST | |||||||||

| TEST METHOD | EN ISO 8491 | EN ISO 8493 | EN 1971 | |||||||||

| EN 1057 | Upto>18mm-MANDATORY | EDDY CURRENT | Up to 159 mm DD | |||||||||

| Upto>18mm-MANDATORY | ||||||||||||

| Up>18mm-MANDATORY | ||||||||||||

| ASTM B 88 | B.153 | ASTM E 243 | ||||||||||

| D>5/8″ 40%, D>5/8″ 30% | EDDY CURRENT | UP to 31/8″ OD | ||||||||||

| D>5/8″ 40%, D>5/8″ 30% | HYDROSTATIC TEST | 35/8″ OD and Above | ||||||||||

| ASTM B 306 | ASTM E 243 | |||||||||||

| EDDY CURRENT | UP to 31/8″ OD | |||||||||||

| HYDROSTATIC TEST | 35/8″ OD and Above | |||||||||||

| SPECIFICATION | Tensile Strength | Elongation | Hardness | Carbon Residuers | Grain Size | |||||||||||||

| TEST METHOD | Mpa | % | Hv5 | mg/ Dm2 | ||||||||||||||

| EN 1057 | EN 10002-1 | EN ISO 6507-1 | EN 723 | |||||||||||||||

| 220 min. | 40 mins | 40 to 70 | 0,2 | |||||||||||||||

| 250 min. | D<66.70&T<1mm-30 min. | D>66.70&T>1mm-20mins. | 75 to 100 | 0,2 | ||||||||||||||

| 290 min. | 3min. | 100 min. | upto54mm-0,20above54mm-1,0 | |||||||||||||||

| ASTM B 88 | ASTM E 8 | E 18 | E2,E3,E112 | |||||||||||||||

| ksi = 1000psi | % | Rockwell | mm | |||||||||||||||

| 30min. | F – 50max | 0.040min. | ||||||||||||||||

| 30min. | F -55max | 0.025min. | ||||||||||||||||

| 36min. | 30T-30min. | |||||||||||||||||

| ASTM B 306 | ASTM E 8 | E18 | ||||||||||||||||

| 40 ksi Min | 30T-30min. | |||||||||||||||||

|

|

|

|

| DWV |

|

|

|

|

|

Nominal O.D |

| Actual O.D |

|

| THK. | Tol. | THK |

| WT/WRONG | WRONG PRESSURE |

|

|

|

|

|

|

|

| Min Thk |

|

|

Inch |

| Inch | Inch | mm | inch | (+/-(inch)) | mm |

| KG | HARD kPa |

|

|

|

|

|

|

|

| Inch |

|

|

1.1/4″ |

| 1.3/8 | 1.375 | 34.925 | 0.04 | 0.003 | 1.016 | 0.0.37 | 0.953 | 3,906 |

1.1/2″ |

| 1.5/8″ | 1.625 | 41.275 | 0.042 | 0.003 | 1.067 | 0.039 | 1.13 | 3,475 |

2″ |

| 2.1/8″ | 2.125 | 53.975 | 0.042 | 0.004 | 1.067 | 0.038 | 1.487 | 2,577 |

3″ |

| 3.1/8″ | 3.125 | 79.375 | 0.045 | 0.004 | 1.143 | 0.041 | 2.198 | 1,883 |

4″ |

| 4.1/8″ | 4.125 | 104.775 | 0.058 | 0.007 | 1.473 | 0.051 | 2.903 | 1,774 |

5″ |

| 5.1/8″ | 5.125 | 130.175 | 0.072 | 0.008 | 1.829 | 0.064 | 3.607 | 1,792 |

6″ |

| 6.1/8″ | 6.125 | 155.575 | 0.083 | 0.008 | 2.108 | 0.075 | 4.312 | 1,756 |

Abco Engineering Inc. stands out as a premier manufacturer specializing in the production of copper pipes, tubes, and brass components. Renowned for excellence, our products find versatile applications across various industries including electrical systems, medical gas pipelines, HVAC and refrigeration, heat exchangers, and automotive sectors.

Shop No.1, Shreepati Castle,

“A” Wing, 11th Lane, Khetwadi, Grant Road,

Mumbai -400004, Maharashtra, India.

Contact No:-9930080011

E-mail ID: info@abcoenginc.in

Abco Engineering Inc. © 2023 Created with YUGASMI