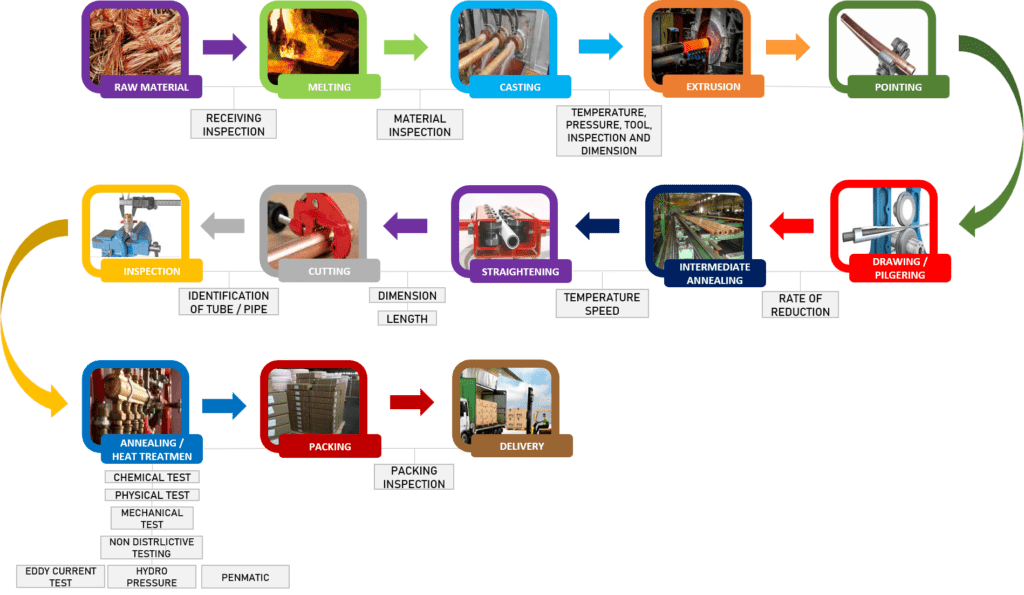

The manufacturing process of copper pipes, tubes, and fittings typically involves several steps to transform raw copper materials into the final products. While the specific details may vary among manufacturers, the general process can be outlined as follows:

Raw Material Selection:

The process begins with the selection of high-quality copper raw materials. Copper cathodes or copper scrap may be used, depending on the manufacturer’s preferences and the desired product specifications.

Melting and Casting:

The selected copper material is melted in a furnace. This molten copper is then cast into billets or logs, which will serve as the starting point for further processing.

Extrusion:

The copper billets are heated and extruded through a die to create long hollow tubes or pipes with the desired diameter and thickness. This extrusion process ensures a uniform shape and size.

Drawing:

The extruded tubes may undergo a drawing process, where they are pulled through a series of dies to achieve the desired dimensions and improve the surface finish.

Annealing:

The drawn tubes are subjected to an annealing process, involving controlled heating and cooling, to relieve stresses and enhance the copper’s mechanical properties. Annealing also improves the tube’s malleability and ductility.

Cutting and Shaping:

The tubes are cut into specific lengths, and various end-forming processes, such as flaring, threading, or soldering, may be applied to create fittings or prepare the ends for connection.

Surface Treatment:

Copper pipes and fittings may undergo surface treatments like pickling or passivation to remove oxides and contaminants, ensuring a clean and corrosion-resistant surface.

Quality Control:

Throughout the manufacturing process, quality control measures are implemented to check the dimensions, integrity, and other critical properties of the copper pipes and fittings.

Testing:

Finished products are subjected to various tests, including pressure testing, to ensure they meet industry standards and specifications.

Packaging and Distribution:

The final copper pipes, tubes, and fittings are packaged and prepared for distribution. They are shipped to customers or suppliers for use in various applications, such as plumbing, HVAC systems, or industrial processes.

Abco Engineering Inc, as a manufacturer in Mumbai, India, would likely follow a similar process, adhering to international standards and industry best practices to produce high-quality copper pipes, tubes, and fittings. Additionally, their specific techniques, equipment, and quality control measures may be proprietary and unique to their manufacturing facility.

| PHYSICAL PROPERTIES OF COPPER & COPPER BASED ALLOY | |||||||

| Density Z Gms/cm | Melting Point | Coefficient of thermal expansion (20-300C )x 10/c | Specific Heat (at 20C) Cal/gm/C | Thermal conductivity at 20C Cal/CM/Sec/C | Electrical Conductivity at 20C% IACS | ||

| Solidus Temp.c | Liquidus Temp.c | ||||||

| Electrolyte CU(ETP) | 8.89-8.9 | 1065 | 1083 | 17.7 | 0.092 | 0.934 | 101% |

| DHP Cu | 8.94 | 1065 | 1083 | 177.7 | 0.092 | 70-87 | 70-80 |

| DPA Cu | 8.94 | 1065 | 1082 | 18 | 0.092 | 35-45 | 35-45 |

| TELLERIUM Cu(0.5 Tel) | 8.94 | 1050 | 1080 | 17.8 | 0.092z | 0.88 | 0.95 |

| 70/30 cartridge Brass | 8.53 | 915 | 955 | 19.9 | 0.09 | 0.29 | 0.28 |

| Admiralty Brass | 8.53 | 900 | 935 | 20.2 | 20.2 | 0.09 | 0.26 25% |

| Aluminum Brass | 8.33 | 930 | 970 | 18.5 | 0.09 | 0.24 | 23% |

| 70/30 Cu.Ni. | 8.94 | 1100 | 1150 | 17.1 | 0.09 | 0.11 | 9% |

| 90/10 Cu.Ni. | 8.94 | 1170 | 1240 | 16.2 | 0.09 | 0.07 | 46% |

Abco Engineering Inc. stands out as a premier manufacturer specializing in the production of copper pipes, tubes, and brass components. Renowned for excellence, our products find versatile applications across various industries including electrical systems, medical gas pipelines, HVAC and refrigeration, heat exchangers, and automotive sectors.

Shop No.1, Shreepati Castle,

“A” Wing, 11th Lane, Khetwadi, Grant Road,

Mumbai -400004, Maharashtra, India.

Contact No:-9930080011

E-mail ID: info@abcoenginc.in

Abco Engineering Inc. © 2023 Created with YUGASMI